Importance of Copper in Medical Applications

Why Copper is a Game-Changer in Medicine

Copper isn’t just a shiny metal—it’s a lifeline in medical innovation. Picture this: a hospital bustling with cutting-edge devices, from surgical tools to implantable devices. What silently powers their effectiveness? Copper. This unassuming hero plays a pivotal role in keeping modern healthcare safe and efficient.

But why? Copper’s arsenal of benefits is practically unmatched. For starters, it has exceptional antimicrobial properties. In a world where infection control is critical, especially in hospitals, copper surfaces act like tiny germ assassins, killing bacteria within hours of contact. It’s no wonder you’ll find copper alloys in everything from doorknobs to IV poles.

- Energy conduction: Devices like MRI machines and pacemakers rely on copper for flawless transmission.

- Corrosion resistance: Imagine a device implanted in a human body—copper ensures durability without breaking down.

- Biocompatibility: Need we say more? Copper works harmoniously with the human body.

Whether it’s enabling non-invasive diagnostic tools or reducing hospital infections, copper is truly the unsung cornerstone of medical progress. It isn’t just in the background—it’s the reliable partner every practitioner leans on. Could there be a better foundation for saving lives?

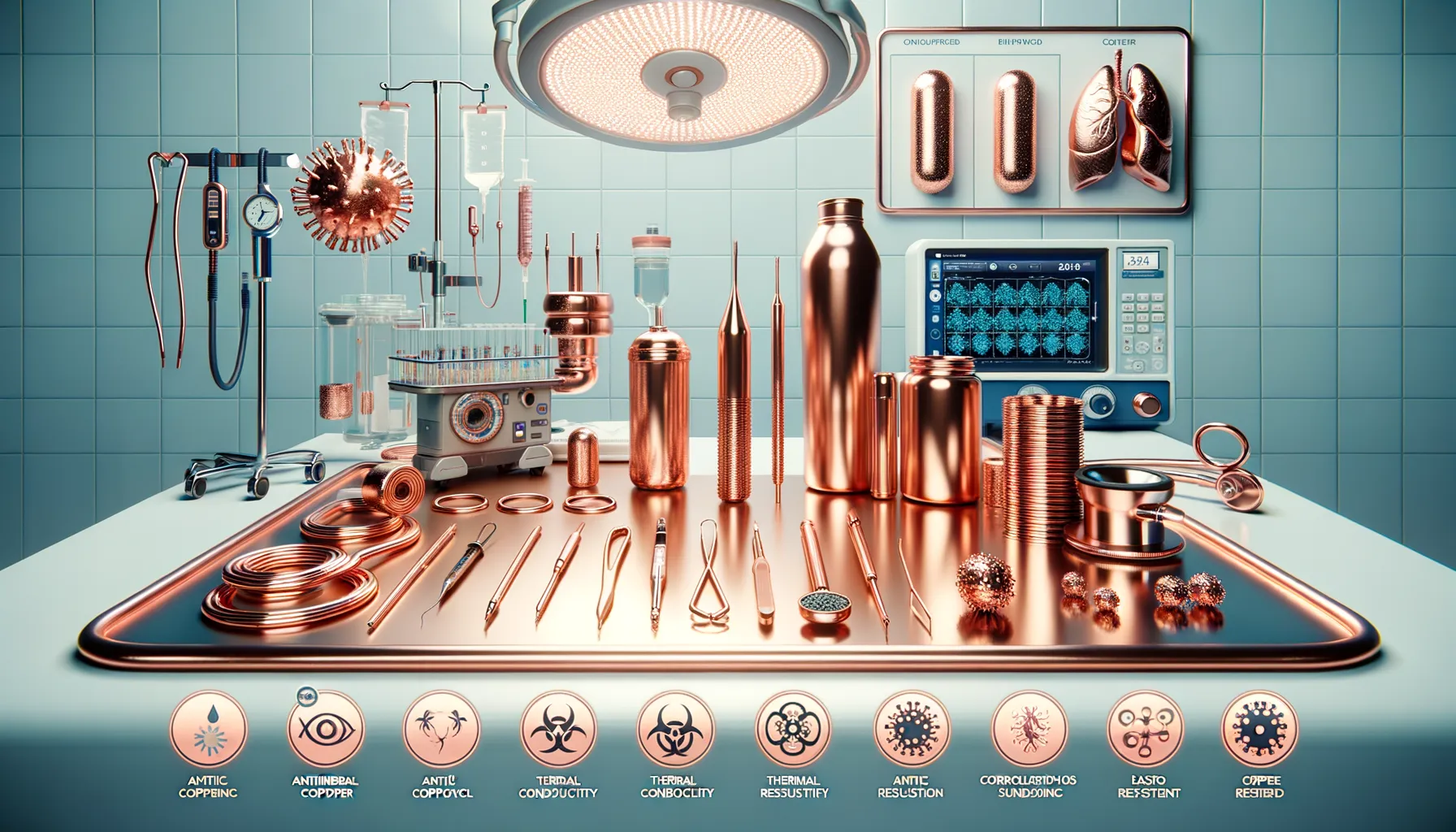

Copper’s Key Properties for Medical Devices

Why Copper Shines in Medical Technology

Imagine a material that’s as versatile as it is reliable. That’s copper for you—a backstage hero in the medical world. Its properties make it nothing short of essential, especially when human lives depend on precision and safety.

What makes copper so unique? Let’s dive in:

- Antimicrobial Superpower: Copper isn’t just tough—it’s deadly to microbes. A sterile environment is critical in healthcare, and copper delivers by actively destroying bacteria, viruses, and fungi on its surface.

- Electrical Excellence: Many modern medical devices rely on flawless conductivity. From MRI machines to compact medical implants, copper keeps the current flowing without a hitch.

- High Thermal Conductivity: Heat-sensitive equipment? No problem. Copper dissipates heat efficiently, keeping devices functioning at optimal temperatures even in high-stakes surgeries.

The Flexibility You Didn’t Know You Needed

Medical innovation demands materials that can adapt. Here, copper flexes its metaphorical muscles. This metal is pliable yet strong, effortlessly shaped into wires, tubes, or intricate components like stents.

Take surgical tools, for instance. Copper alloys allow precision manufacturing of instruments that surgeons trust with their hands—and their patients’ lives. Plus, its biocompatibility ensures it works harmoniously with the human body, reducing risks when used in implants.

Copper, quite simply, is the unsung architect of cutting-edge medical technologies.

Applications of Copper in Medical Device Manufacturing

Revolutionizing Surgical Tools with Copper

When it comes to surgical instruments, precision and reliability aren’t negotiable—and that’s where copper steps in as a true game-changer. Imagine the tools a surgeon uses: scalpels, clamps, forceps. These aren’t just instruments; they’re lifelines. By incorporating copper alloys into their design, manufacturers elevate these tools to a whole new level of performance.

Copper’s natural antimicrobial properties are its superpower here. It actively fights bacteria on contact, reducing the chances of infections spreading during delicate procedures. No wonder it’s becoming a top choice for medical device coatings! Think of it as a quiet guardian working overtime beneath the surface.

- Scalpels with sharper edges and improved sterility.

- Surgical robots enhanced with copper components for added efficiency.

- Even implantable devices lined with copper to prevent microbial buildup.

Enabling Advanced Diagnostic Equipment

Ever marveled at the intricate dance of a CT scanner or MRI machine? Here’s an insider tip—the magic often lies in the exceptional conductivity of copper. High-tech diagnostic devices rely on copper’s ability to conduct electricity and heat seamlessly, ensuring accurate results and smooth operation. From the wiring that powers imaging machines to the heat sinks that keep them cool under pressure, copper is in the background, silently making miracles happen.

It’s not flashy, but without copper, your next X-ray might not even work! Quite literally, it’s the metal that keeps the heart of modern medicine beating.

Advantages of Using Copper in Healthcare Industry

Why Copper is a Game-Changer for Healthcare

Did you know that something as simple as copper can revolutionize the way we approach health and hygiene? It’s not just a metal; it’s practically a superhero material in the healthcare industry. Imagine a hospital where every touchpoint—door handles, bed rails, IV poles—is made safer thanks to copper’s remarkable properties. Sounds futuristic? It’s happening now!

Copper is naturally antimicrobial, which means it *actively* works to destroy harmful bacteria, fungi, and even viruses the moment they touch its surface. Think about it: where stainless steel might stubbornly hold onto germs, copper essentially gives them a one-way ticket to extinction. This quality makes it a lifesaver (literally) in critical environments like operating rooms and ICU wards.

- Durability: Copper doesn’t just fight germs—it outlasts traditional materials under constant cleaning and sterilization.

- Conductivity: With its unmatched electrical and thermal conductivity, copper is vital in precision devices like MRI machines and pacemakers.

- Sustainability: 100% recyclable and abundant, copper ticks the eco-friendly box. That’s innovation with a conscience!

When was the last time you looked at copper and thought, “game-changer”? Well, now might be the time to start.

Future Trends and Innovations in Copper Usage

Revolutionizing Healthcare with Copper’s Emerging Potential

The horizon of copper innovation is glimmering brighter than ever, with creativity driving its adoption in groundbreaking ways. Imagine a world where medical devices are not just tools but active participants in healing. That’s precisely the direction we’re heading with the latest developments in copper usage.

Emerging technologies are tapping into copper’s intrinsic properties—its superior conductivity, antimicrobial prowess, and malleability—to revolutionize patient care. For instance, researchers are exploring copper-based nanocoatings for surgical tools that could actively reduce infection risks. Think about it: a simple tweak in material composition that could save lives.

- Flexible copper circuits may soon enable wearable health monitors that mold to your body like a second skin.

- Advances like copper-infused 3D printing filaments are creating custom implants tailored precisely to individual needs.

Pioneering Sustainability in Medical Manufacturing

Copper’s future isn’t just about cutting-edge tech—it’s green too. With its recyclability, copper is being incorporated into sustainable manufacturing processes. Picture this: a hospital ecosystem where essential medical devices are built using reclaimed copper, reducing waste and environmental impact.

And let’s not forget the electrifying role copper is playing in energy-efficient solutions, from powering portable devices to enabling wireless charging stations in hospitals. This isn’t just progress; it’s copper building a cleaner, smarter healthcare system.